28.01.26PI_646

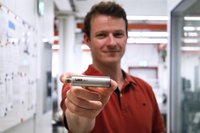

ROEMHELD präsentiert neuen innovativen Kompaktspanner mit patentierter Kinematik

Erstmals direkt in kleinsten geschlossenen Taschen, Nuten und Aussparungen spannen

Ohne zusätzliche Spannstellen und Platzbedarf für die Hebelbewegung

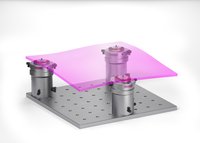

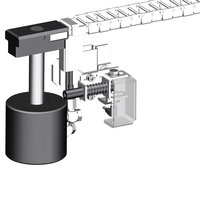

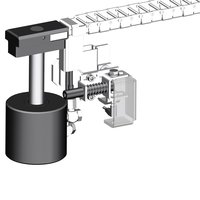

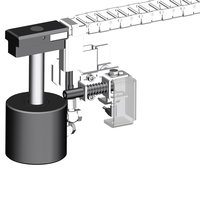

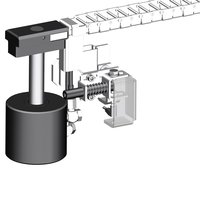

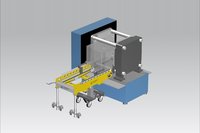

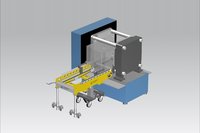

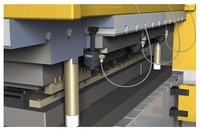

Laubach, den 28. Januar 2026. Ein neu entwickelter hydraulischer Kompaktspanner mit horizontalem Hub ermöglicht erstmals das direkte Spannen in kleinsten geschlossenen Taschen, Nuten und Aussparungen. ROEMHELD hat das Element so optimiert, dass es selbst Werkstücke und Vorrichtungen in beengten Bauräumen mit maximaler Spannkraft und hoher Wiederholgenauigkeit spannt.

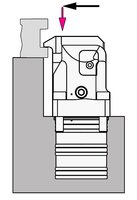

Die Innovation liegt in der bislang weltweit einzigartigen, patentierten Kinematik: Der Spannhebel bewegt sich zunächst horizontal in die zu spannende Stelle des Werkstücks. Anschließend spannt er vertikal nach unten. Dieser Bewegungsablauf erlaubt eine platzsparende Werkstückaufnahme mit exakter Positionierung.

Bisher mussten Zerspaner bei solchen Spannaufgaben Bauteilen oft zusätzliche Spannstellen hinzufügen und diese in Folgeoperationen wieder entfernen. Die hierbei verursachten Mehrkosten und verlängerten Prozesszeiten vermeidet der neue Kompaktspanner.

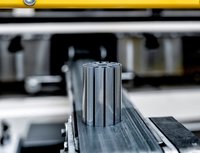

Er eignet sich insbesondere für Gussteile, Werkzeuge, Formen und Vorrichtungen, die in sehr schmalen Nuten, Aussparungen oder Taschen gespannt werden müssen. Typische Einsatzfälle finden sich in der Mehrseitenbearbeitung von gegossenen Werkstücken aus Aluminium oder Grauguss.

Die Langfassung des Textes als Word-Dokument und das Bildmaterial in Druckauflösung erhalten Sie, wenn Sie den zip-Dateiordner herunterladen.